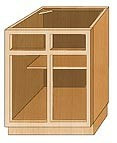

CABINETS 101

Helping you understand the ins and outs of cabinetry

Cabinet options including door styles, wood types, finishes, mouldings and organization solutions gives you a wide range of possibilities to make your dream room come true. These choices can be overwhelming, though, if you don’t have a basic understanding of cabinets. Recognizing the differences between cabinet construction types, materials and quality will help you understand the wide price variance in the kitchen cabinet market.

Cabinet options including door styles, wood types, finishes, mouldings and organization solutions gives you a wide range of possibilities to make your dream room come true. These choices can be overwhelming, though, if you don’t have a basic understanding of cabinets. Recognizing the differences between cabinet construction types, materials and quality will help you understand the wide price variance in the kitchen cabinet market.